Introduction

Chase Petroleum, a major player in fuel storage and distribution, faced severe corrosion at the chime areas of their fuel storage tanks, where water and sediment accumulation heightened the risk. To address this, Chase Petroleum enlisted Vulcan Holdings Limited (VHL), a corrosion control expert. VHL offered our Visco-elastic tank chime protection system, known for its self-healing properties and strong adhesion, to effectively tackle the corrosion issue.

Problem Statement

Chase Petroleum faced a severe and persistent corrosion problem at the chime areas of their fuel storage tanks, where the tank wall meets the floor. Initially, a bitumen coating was applied to combat corrosion, but it failed over time, developing cracks, and disbondment. This led to severe corrosion due to water and sediment ingress, causing product leakage, contamination, high maintenance costs, operational downtime, and increased safety risks. The situation highlighted the need for a more effective and durable solution to ensure the long-term protection and functionality of the tanks.

Solution

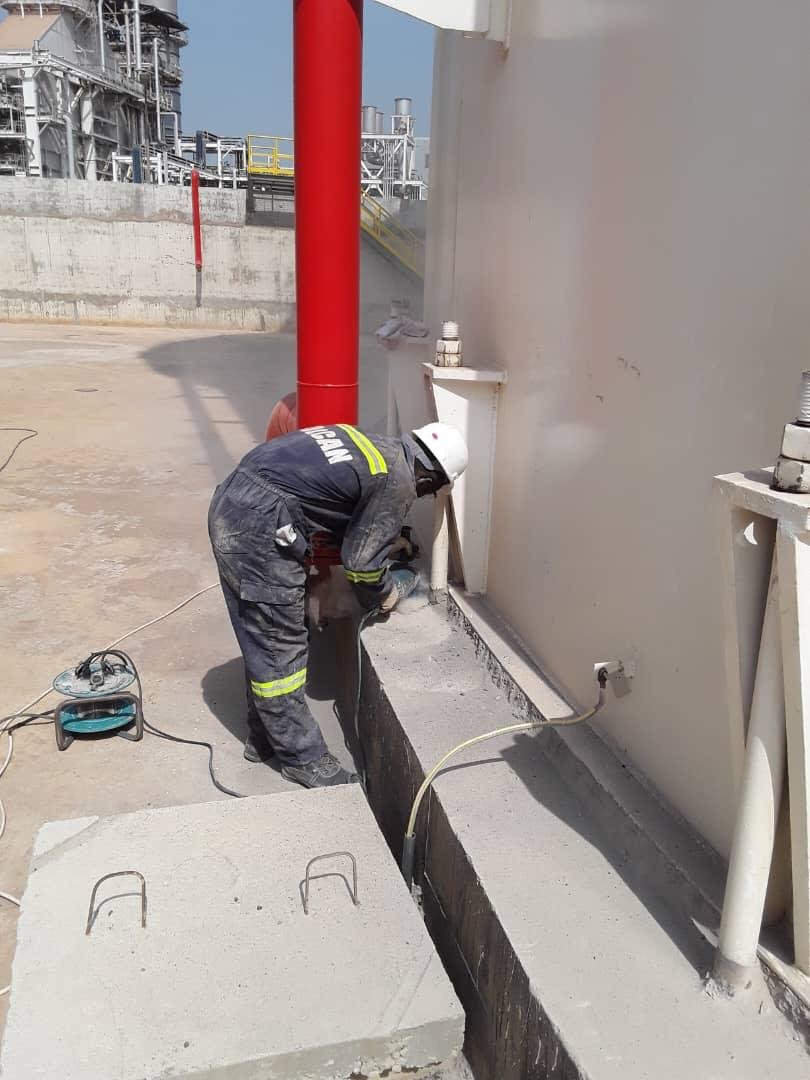

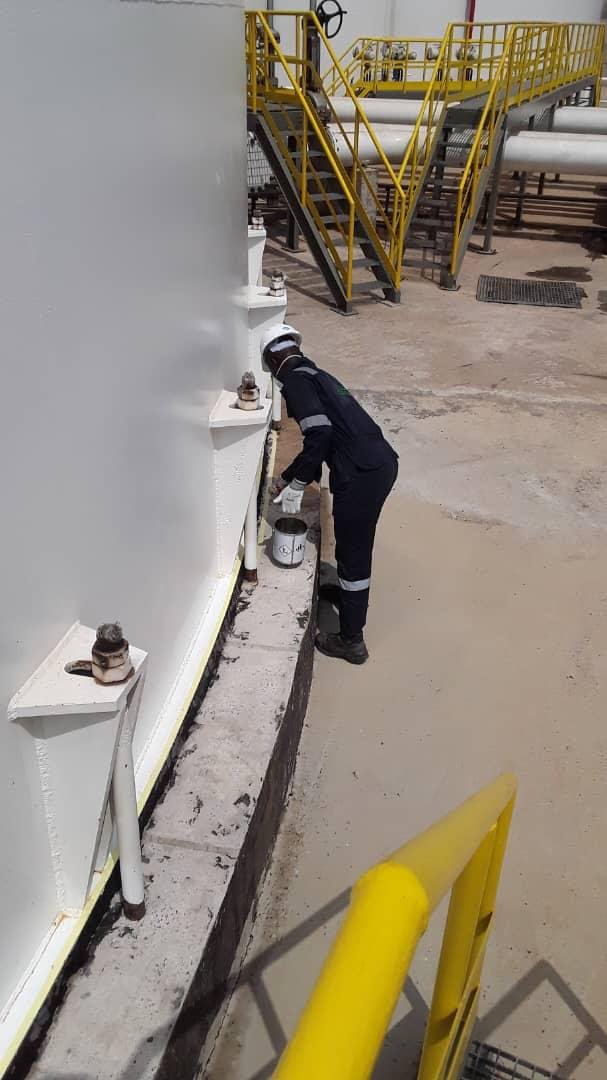

To resolve the severe corrosion issue, VHL used our STOPAQ Visco-elastic tank chime protection system. This system, known for its self-healing properties and superior adhesion, provided a long-lasting solution with a thirty-year service life. VHL began by thoroughly preparing the tank chime surfaces, and removing all bitumen, rust, and debris through meticulous cleaning. The STOPAQ system, including STOPAQ 4200 Filler, EP Primer, and EZ Wrappingband, was then applied. The Wrappingband’s flexibility ensured complete coverage of the tank chimes, while its self-healing feature sealed any damage automatically. An aesthetic UV-resistant paint, EZ Topcoat, was applied for additional UV protection. After application, a detailed inspection ensured proper coverage, and touch-ups were made as needed to guarantee optimal protection.

Outcome

The implementation of the new system provided outstanding corrosion resistance, effectively preventing further damage from water and sediment at the tank chimes. This led to an improvement in the operational reliability of the storage tanks, significant reduction in maintenance costs, with no repairs and replacements needed since the system has a service life of over 30 years. Enhanced safety conditions also resulted, as the system minimized the risk of leaks and potential hazards, safeguarding both the facility and the environment.

Images From Projects